Controlled

manufacturing

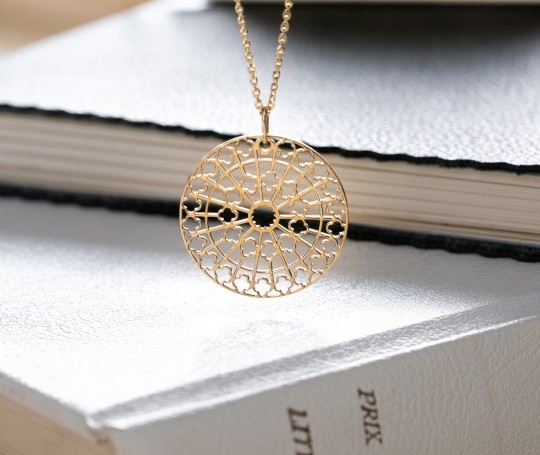

All our jewellery is designed in our offices by our creative jewellers in consultation with our diamond and gemologists, and is manufactured in our workshops or by recognised specialists. All our chains, for example, are made in Italy by master chain-makers.

Drawing

It is then computer modelled to see how the model can withstand the physical constraints. Once the model has been produced, any finishing touches need to be fine-tuned.

The creation

A wax model of the prototype is then created from the design. This represents the jewel in its exact proportions, with the locations reserved for the precious stones or semi-precious stones that have been selected.

Jewellery making

The approved wax prototype is then sent to our production workshops to be transformed into a piece of jewellery.

This is where our jewellers make the mould from the wax model.

The precious alloy is then poured into the mould and cooled to form the body of the jewel.

The raw creation will be soldered and filed by our goldsmiths before passing into the hands of a setter.

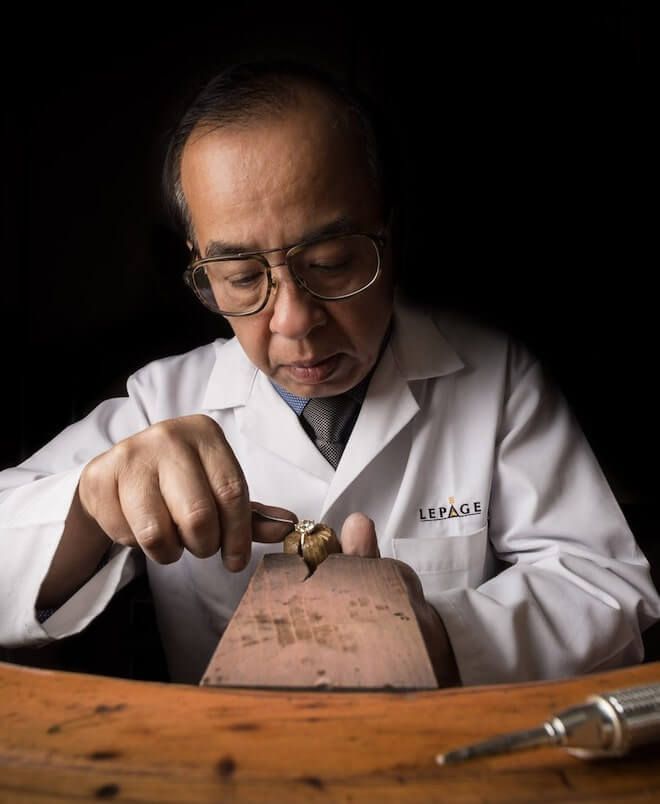

Crimping

Setting is a meticulous process that involves fixing the gemstone in a small cavity called the ‘bezel’, using a variety of methods, before folding back the claws (or other means) that surround it to hold it firmly in place.

Polishing and rhodium-plating

The approved wax prototype is then sent to our production workshops to be transformed into a piece of jewellery.

This is where our jewellers make the mould from the wax model.

The precious alloy is then poured into the mould and cooled to form the body of the jewel.

The raw creation will be soldered and filed by our goldsmiths before passing into the hands of a setter.

Punching

The final creative step is to strike the jewel with a small hammer, called a punch, to authenticate it.

The master hallmark: As a jewellery manufacturer, Maison Lepage has its own master hallmark which we affix to our jewellery to ensure optimum traceability.

The State hallmark: This hallmark guarantees the purity of the metal used. At Lepage we have obtained an approval agreement from the guarantee office. We are subject to strict regulations that guarantee the precious metals and their origin. All our jewellery is hallmarked with an eagle's head, corresponding to 750 thousandths gold, or a wolf's head for platinum.

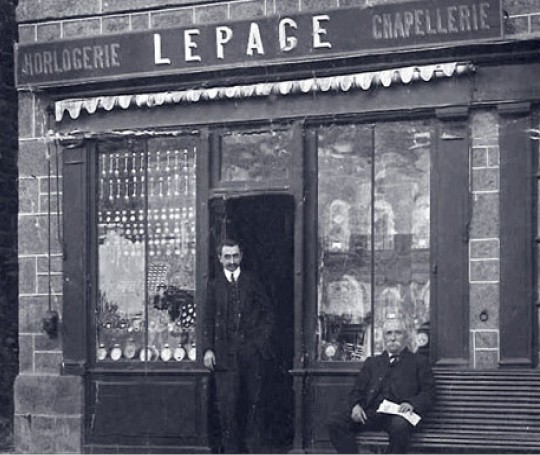

Setting the scene

Today, Lepage continues to write its history in line with contemporary trends and developments.

With the return of the Lepage collections in 2019, our jewellery house is perpetuating its heritage through almost a century of excellent craftsmanship.

Immerse yourself in the history of Maison Lepage, from the 19th century to the present day. An epic story spanning five generations of jewellers, from the confines of Normandy to the digital age.